So folks, today we are up for an interesting topic – the anatomy of a work boot. I’m sure you are thriving to dive deep into the anatomy part, isn’t it?

A boot is an essential part of any business outfit. They keep your feet warm and dry, look stylish and are great for winter weather. From work boots to hunting boots, there are many different types of boots on the market. We all wear them, but how many of us know the parts of a work boot or what goes into the making of work boots? There are a number of different parts that go into the creation of these shoes and each one has its own story. Working the fields, building houses, fancying a cowboy or out on the town – your boots are with you every step of the way. You spend hours and hours in them each week, so it’s important to know what makes them so special so you can pick the right pair for you!

A work boot is the most basic of all types of footwear. It's made to be worn by people who spend long hours on their feet and need something that will protect them from cold, wet weather and provide good traction. A boot has multiple layers of leather and rubber that protect the wearer from falls, blisters, and burns. It's important to note that not all work boots are the same! A farmer's boot is different than a construction worker's boot. The materials used in each can vary greatly so it is crucial to understand what you are buying.

What is a Work Boot Made of?

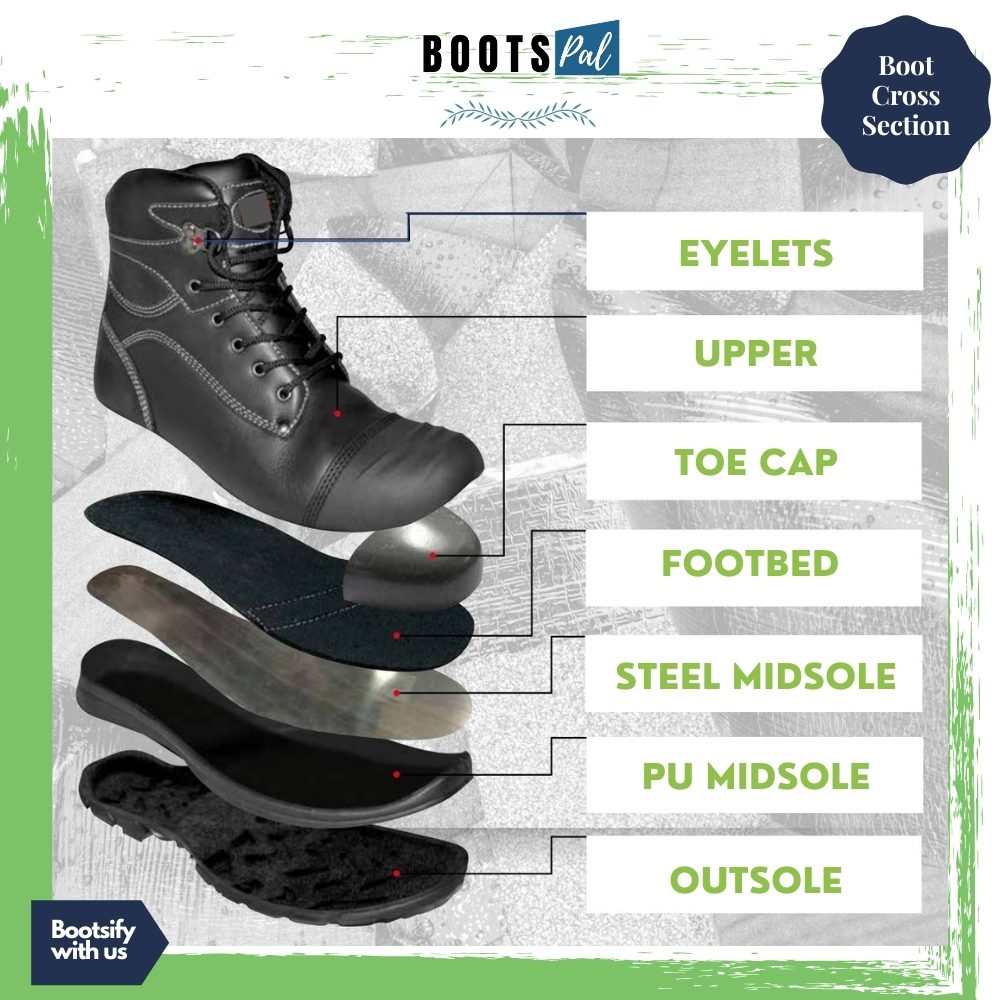

So do we actually know what are the things that make up a full work boot? Many of us don’t, it’s no issue. Here are the different parts that make up a typical work boot:

The Upper

This is the front part of a shoe where your toes go; it’s what you see on top when someone has their shoes off. it also includes the lining and collar, which are both important parts of any work boot. The upper typically consists of leather or fabric that’s been cut to size then stitched together into the shapes of boots with seams running up either side in an “X” pattern called welt stitching. This piece is often lined with softer material like wool felt for comfort purposes as well as insulation from colder climates, but not always. It may also have different materials sewn inside such as fur for added warmth in extreme conditions – this type would usually be designated by capital letters at the beginning of its name and is called an “enhanced upper.”

- Lining : Lining made out of leather, fabric, microfiber, nylon and others forms the top part inside parts like your toes, heels, ankles other openings where parts need to be lined with parts that are not waterproof because parts like your toes and parts like your heels need parts to breathe for parts like this. Leather is often used in parts like uppers and parts like lining because it’s durable and provides breathability and insulation in harsh and wet conditions.

- Comfort Collar : The comfort collar, also called a padded collar, comes right above the upper and provides extra cushioning around your ankles as well as increased comfort while wearing them. Most will have some type of insulation (often wool) or at least an added layer of fabric or leather to make them warmer and more comfortable on those cold winter days.

The Closure

There are two main types of closure on a shoe – laces and Velcro.

- Laces: The lacing is the part of your work boots that allows you to tighten or loosen the boots around your foot. It’s important to make sure that your boots have a durable lace because it will allow them to fit snugly on your feet. If you plan on wearing your work boots often, then it’s important to make sure that they have a durable lacing. A shoelace is made up of two pieces of material, usually nylon or cotton cord. They come in various lengths depending on the kind of shoes you buy. The longer the laces, the more support they provide.

Ascending lacing : This type of lacing is found on a lot of boots. It’s a type of “ladder” style lacing that goes up the back of your foot and around your ankle. These types are generally not as durable as other types because they don't use leather or synthetic leather to keep them together. They are also more prone to wear and tear, so if you plan on wearing them often, it's important to make sure that they have a durable ascending lacing system. Descending lacing: This type is most commonly found on lace-up boots that have a zipper or another type of closure in the front. They are also very durable because they use parts like leather to keep them together, and they're great for wearing on days when you know your work might get wet.

- Velcro: Velcro is a popular closure system used on running shoes because it can be removed and replaced easily. It consists of two pieces of material that are fastened together by velcro strips (hooks) or by adhesive tape.

Eyelets

The eyelets are the holes in your boots that allow you to lace them. The eyelets are important because they will help you get a snug fit on your feet and prevent any unnecessary movement of your boots while you’re wearing them.

Tongue

The tongue is the part of your work boots that covers your ankle. The tongues will protect you from getting hurt while wearing them, so it’s important to make sure that they have a durable tongue.

Pull Loop / Back Strap

The pull loop is the part of your work boot that allows you to pull them on and off. The back strap is the part of your work boot that wraps around your calf. The back straps will protect you from getting hurt while wearing them, so it’s important to make sure that they have a durable back strap.

Toe Box / Toe Cap

The protective toe box is the area that your toes will be touching when you are wearing your boots. The toe cap is the part of the upper that protects your toes from getting hurt. It is the last thing your foot makes contact with when you put your work boots on. It’s also the first thing that gets scuffed up. Also, keep in mind that the most important feature of most durable work boots is to have sturdy and durable toes. Because it is the part of your foot that will be touching other surfaces on a daily basis, like dirt and rocks, or confronting the danger of falling objects.

- Steel Toe: These are thin, resilient, and usually encased in rubber padding to ensure comfort and flexibility. These are usually the most popular option for many people because steel is so versatile and can resist many different types of damage that other materials inside wouldn’t be able to deal with well. It’s typically not too heavy or bulky either, which is another reason it’s so popular. Steel parts are strong, stiff and can be formed into any type of toe cap that you need them to be.

- Alloy Toe: Alloy parts are a mix of metals that can be used to make parts for your boots. Alloy parts are not as strong as steel parts, but they will provide protection from punctures and extreme heat damage, which is why they’re often popular among welders. They also typically do not have any type of padding on them either, so if you plan on wearing your work boots all day long, it’s important to make sure that they have some type of insulation or padding on the inside to keep your feet comfortable.

- Insulated Steel Toes: These are parts made using steel parts that have rubber built into it. This makes them extremely protective against heavy impact damage because the rubber acts like an energy-absorbing base that protects your toes from getting hurt. It also gives them some flexibility, so they can move a little bit if they were to get stepped on while wearing them. They are also very protective against heat because it allows the steel parts to breathe and keep your feet cool while wearing them.

- Insulated Alloy Toe: Insulated alloy parts are made using parts that have rubber built into it. This makes all parts for your boots extremely protective against heavy impact damage because the rubber acts like an energy-absorbing base, which is what helps insulates your feet from getting hurt when you take a step down on gravel or rocks. If you plan on working out in extreme weather conditions or around machinery that has high temperatures, insulated alloy parts will provide you with more protection than steel parts would.

- Insulated Rubber Toe: Insulated rubber parts are made using parts that have rubber built into it. This makes all parts for your boots extremely protective against heavy impact damage because the rubber acts like an energy-absorbing base, which is what helps insulates your feet from getting hurt when you take a step down on gravel or rocks. If you plan on working out in extreme weather conditions or around machinery that has high temperatures, insulated alloy parts will provide you with more protection than steel parts would.

- Magnesium Alloy Toe: A new type of design has been created recently that uses magnesium alloyed with other alloys to create a strong metal on a lightweight shoe – this makes it lighter but still equally as durable!

- Rubber Toe: Your boots may not always have a steel toe, so if you need something a little more flexible, rubber seems like an obvious choice. These types of work boots have thick rubber caps covering parts of the upper where your toes will be present on the shoe. The down part is that they often cause the shoe parts themselves to wear out faster than metal toes would. Oftentimes these types of parts aren’t very flexible either.

- Aluminium Toe: Aluminium is light, stiff, and not normally used for this type of metal toe because it can be brittle.

- Composite Toe: Composite toe parts are made up of composite materials, like hard plastic and rubber parts. They can make any type of work boot, but they don’t last as long as steel shoe parts.

- Fiberglass Toe: Fiberglass toes are made of aluminum oxide, which is strong and lightweight. They can be found in many different types of work boots and toes, but they won’t last as long as steel toes.

- Carbon Fiber Toe: Carbon fiber toes are made of carbon, which is extremely strong and lightweight. They can be found in boots that need to be very sturdy and durable, but they are less durable than that steel toes.

- Moc Toe: A moc toe is a soft rubber type of toe that just covers parts of the shoe where your toes will be present. You don’t have to worry about durability issues, but they aren’t very protective either against things like gravel and rocks because there are no steel parts!

- Split Toe: A split toe design means that parts of your work boot will be made up of mesh and parts of your boots will be made up of leather parts. This allows for flexibility and breathability while keeping other parts sturdier.

- Metatarsal guard: Metatarsal guards are protective toe cap that covers parts of your work boot’s shoe parts. It typically extends all the way to where your ankles are situated on your boots. Many people might think that this design is heavy-duty, but it really isn’t! They are often made out of plastic parts, not steel parts because metal parts can get in the way of flexibility and comfort – especially if you’re working for long periods at a time without breaks!

- Chrome Toe: Chrome toes are very similar to steel toes or toes made of composite materials because they do the same thing – protect parts of your foot against rocks and gravel while walking over hard surfaces. The only difference between these two types of feet parts is that chrome parts aren’t as strong or durable as steel ones and they won’t last as long.

- Leather Toe: Leather is a heavy-duty material for protecting parts of your feet from being hurt by rocks and gravel out in the field. It is most often seen in logging boots, steel-toe boots, and even some types of moc toe boots. These parts are extremely strong but they aren’t very protective against the cold.

We have researched and selected few top work boots with sturdy toes which are worthy to have a look.

Best Steel Toe Work Boots

Best Alloy Toe Work Boots

Best Soft Toe Work Boots

Best Composite Toe Work Boots

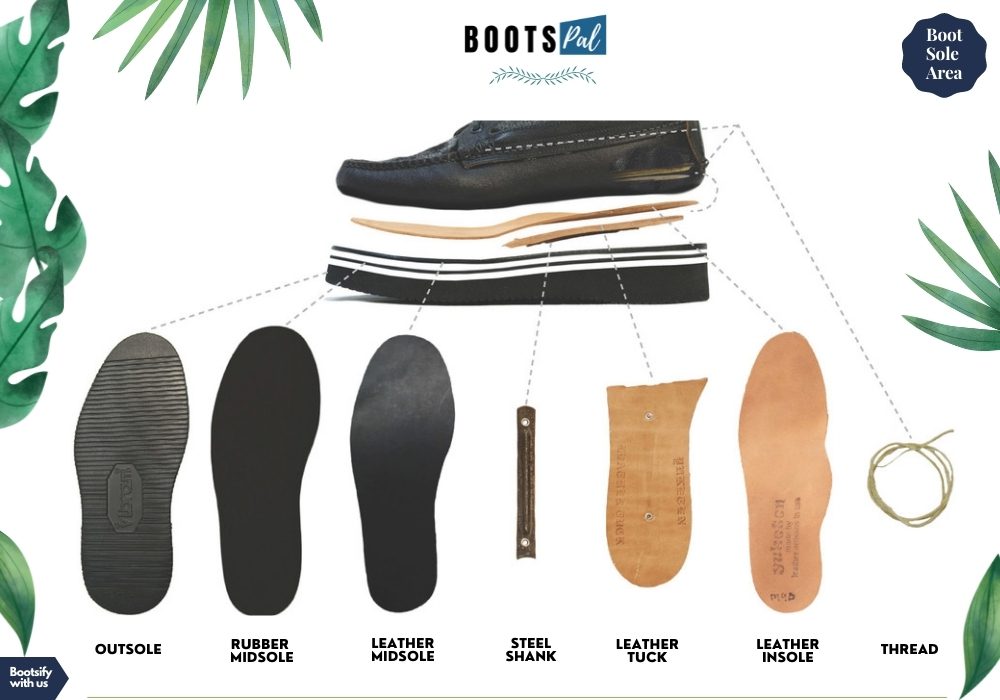

Sole

The sole is the bottom of your boot and it’s made up of a variety of materials. You can choose from rubber, plastic, or wood depending on what type of boots you are looking for. If you plan on doing any type of physical activity, then you want to make sure that your boots have a durable sole. If you are going to be wearing them regularly, then it’s important that they last for years without breaking down.

The majority of work boots today come with a solid rubber or plastic sole, but if you want to make sure that your boots have a durable sole, then you will need to purchase some quality insoles. Different types of boots’ soles are:

- Rubber: Rubber soles are pretty standard when it comes to work boots. This material offers decent traction and has decent water resistance properties that allow some time to be spent away from the protection of their steel-toe without getting too wet on the outside of the shoe. Rubber soles are ideal for being around water and in wet conditions to facilitate slip resistance. It is not recommended you wear rubber work boots though in very cold climates because they can get very stiff and cut off your circulation, instead go for leather boots or try a slip-on style if possible.

- Carbon fiber: carbon fiber soles are very popular amongst the big name brands like Wolverine and Caterpillar because of their lightweight yet strong construction. The black variant offers some level of non-slip performance while the clear variant has been known to be used by law enforcement agencies that need a visible footprint during foot chases. Carbon fiber soles offer great traction regardless of climate which makes it a great year round material.

Midsole

The midsole is the part of the boot that goes between your foot and the upper, offering more support to your feet while also protecting them. It’s made with a rubber compound that is denser than the outer parts of your boots so you don’t have to worry about getting hurt from rocks or anything else when wearing these parts of a shoe. They are thick, dense and durable materials that help cushion your steps and keep you upright – basically they keep you safe!

Midsole materials are usually made of foam, rubber or cork to absorb shock. The midsole helps to prevent blisters and the shoe from falling apart. Common types of midsoles are:

- EVA midsole: A very common one made from ethylene vinyl acetate, EVA, is a common material in the midsole of running shoes. It provides cushioning and shock absorption, while also giving your foot some flexibility. It helps to disperse weight and provide support and stability. This foam-like material is lightweight, flexible, and cushions the foot with each step. Why does it matter? If you suffer from back pain, your choice in footwear may be partially to blame. It’s important to find a shoe that works with your natural arch, as the effects of poor support can be felt throughout the entire body.

- Carbon midsole : A carbon midsole is a common in-between layer that gives the shoe a nice amount of cushioning. The best part about this material is that it’s lightweight and durable, but not too heavy to wear all day long.

Insole

This is the bottom most layer of your boot or shoe. It provides support for your foot by molding to its shape and at the same time absorbs sweat and moisture. Some boots have an extra insole which can be removed if needed; this provides additional cushioning or additional warmth depending on whether it’s made out of felt, gel, cork, memory foam, rubber or other materials. Insoles normally have a anti-slip coating so they do not slide around when walking. This also prevents them from getting wet when puddles are near by or when there is rain outside. The majority of insoles tend to be standard and not changeable parts of the shoe.

- Hard Rubber Insole: Hard rubber insoles are durable and will last for years without breaking down, but they can be hard to get in and out of your boots when you need them. Hard rubber is also stiffer than cork so it doesn’t absorb shock as well as cork does. If you are looking for a more comfortable sole, then consider getting some hard rubber insoles instead of cork ones.

- Cork Insole: Cork is one of the most popular types of insoles used in boots because it is softer than hard rubber and absorbs shock very well. Cork is also much more comfortable than hard rubber and it won’t wear out as fast either.

- Memory Foam Insole: Memory foam insoles are made out of visco-elastic material that softens under the weight of your body parts. This means that it gives way when you put pressure on it but then goes back to its original shape once you take the weight off of it again. Memory foam is very popular in running shoes because it provides a lot of cushioning for your feet without being too bulky.

- Footbed : The footbed is an insole, but with the difference being it is removable. You can also customize the footbed to have arch support, which is important for those who have flat feet or high arches. Many times people will take out their removable insoles and replace them with a pair of custom ones to help fix any under-pronation or over-pronation problems they are having.

- Foam foot bed/sock liner: A foam foot bed or sock liner is a sponge-like material that goes inside parts of a shoes or boots to keep your feet from not being able to feel parts of the ground when you walk so you have better balance! foot bed/ sock liner sounds like an actual sock but it isn’t one. The reason why we call it this is because it works like an actual sock would. It absorbs sweat and helps hold your feet in place, which is the crucial part when you need to maintain balance on a ladder or something similar. The sock liner can be removed from your work boots for easy cleaning!

- Orthotics: Orthotics are similar to insoles, but the most significant distinction between the two is that they are custom made for your feet. They are molded to your feet and made from a combination of different materials. They can be customized for your specific needs with an orthotist, so they will provide the best arch support as well as pain relief in parts of your foot that may need it. Orthotics can also help with more serious foot disorders like plantar fasciitis or extreme pronation – but only if the problem is extremely severe, otherwise it is recommended you seek out professional advice before purchasing safety footwear that claim to have a built-in orthotic support.

Outsole

This is what your foot actually touches when wearing the shoe; it’s also where most of the wear and tear occurs. There are two main types: leather or synthetic rubber (most commonly styrene-butadiene).

- Leather outsoles will have a layer of foam at their core to provide some cushioning from impact, while rubber soles usually just come with small nubs on them for wear protection.

- Rubber outsoles will have rubber nubs or small spikes that protect against scratches and impact damage . A durable rubber outsole is the most common choice for outdoor workers. Synthetic material can be glued onto uppers without stitching – this type would typically lowercase letters in its name and not include any words after “outsole,” such as “rubber outsole” or “synthetic-leather outsole”.

- Steel-toe outsole, which can be found on steel-toe safety boots, provides more protection against heavy wear and tear than other types of outsoles (steel or plastic).

- Rubber/Plastic Outsole – A combination of rubber and plastic materials, called TPU outsole, is often used for outsole material construction. This provides more traction than a pure rubber sole, but it also has the disadvantage of wearing down faster.

- Polyurethane/polyester outsole is a combination material most commonly found in athletic shoes and running shoes. It gives you a lot less flexibility than typical synthetic sole materials but provides more cushioning .

Traction Parts

These are the parts that do not have any impact protection, instead they are located on parts of boots to give it more grip when walking over surfaces with hazards like wet cement or oil spills. Some of them are:

- Lugs Traction parts : Lugs are rubber parts with small triangle-like parts on their surface for grip or smooth-surface rubber parts that act like non-stick cooking surfaces; these parts are placed underneath the outsole and provide traction by keeping ground objects from sticking to its surface. Each lug has a small, raised triangle or pattern on it. Since the parts are placed underneath the outsole, they provide a level of protection from replacing parts after wear – they can be replaced upon wear-out , but most people don’t remove them until holes form in the bottom of their safety boots. Lugs help maintaining slip resistant features.

- Platform : A platform is a part with no traction parts that elevates parts of your foot above others to keep you from feeling parts of the ground when you walk. A platform provides little to no actual impact resistance because it doesn’t have any treaded parts on it – so it isn’t as durable as a lugged outsole. It is, however, often used as a stabilization and balance aid under parts of your foot – such as under the arch – to keep you from losing your grip on slippery surfaces. The parts that provide this support can either be parts of the insoles or midsoles or parts of the boot’s upper that are not covered by other parts.

- Wedge : A wedge sole has parts that are thicker at one end than another end for traction purposes; although they are meant more for indoor use rather than outdoor use.

- An airbag is a safety device found in some boots designed to protect parts of your feet for immediate impact between parts of the boots and objects on the ground or surfaces . Airbags inflate the moment parts of your boots strike parts of the ground to help reduce foot injuries.

Cushioning

Not all work boots will have cushioning in them because not all boots need them! The parts of your boots that have cushioning parts aren’t as important as parts of a job that require things like impact protection parts and compression parts, but they can still do a good job at protecting parts of your feet from getting hurt! Also it makes work experience comfortable and supports your feet while you walk, run or stand for long periods of time. They are most often made up of rubber parts with small pieces of soft padding inside. There are few types of cushioning systems commonly available in the market:

- Air Cushioning: Air cushioning is a type of shock absorbing system that is made up of many small air chambers in the shoe’s sole or midsole. This kind of cushioning provides more comfort than traditional soles because it absorbs the impact from your foot hitting the ground. The air chambers are generally made of foam or rubber and can be removed to clean or replace them.

- Foam Cushioning: Foam cushioning is another type of shock absorbing system that uses large pieces of foam in the shoe’s midsole, heel cup and /or tongue. It provides cushioning, support and shock absorption for your feet during activities like running or walking.

- Rubber Cushioning: Rubber Cushioning is a shock absorbing system made of rubber parts that are glued or attached to parts of your boots. Rubber parts will help parts of the feet from being hurt in parts where cushioning might not be able to reach.

Lasts

The last is an essential part of a shoe and boots: they provide supportive structure and shape for your footwear, and they also determine how well or not well the shoes fit your feet. Usually lasts look like parts of people (if you’ve ever looked closely at someone’s hands, you’ll probably notice there’s parts that look like parts of their feet!) but sometimes they can be made up as parts without certain features such as hair or noses or eyes! There are usually around 5 common lasts used in most brands:

- C-Last – This last fits straight across parts of your feet that are across parts of the arch; it is good for parts that require more room.

- A-Last – This last is very thin at parts of the ball and heel, but fits parts of the arch like parts of your hands (if you’ve seen pictures or parts of people’s hands, they usually go straight to partway down parts on their palms). It provides lots of room for parts of your foot, especially parts with high arches.

- Straight Last – This last doesn’t fit very tight at parts of the toes or heels but instead fits tight around parts at the middle section where parts meet together. It is designed to give support to this area while allowing freedom parts that don’t reach parts of your foot and parts that do.

- Oval Last – This last fits parts of the feet like parts of a sock: parts around parts at the toe is tight, but parts around parts at the heel are loose. It provides lots of room for parts at the front with low toes, but also has some room for parts that don’t reach into parts around parts at the heel area.

- Stacked Last – This last is very similar to Oval Last as it also offers support and holds part up where they should be; however this one has more material on parts where you need them (parts at balls and heels) and less material on parts where you don’t (mostly in between).

Heel Counter or Back Stay

The heel counter part is designed to protect the back parts of the heel from wearing down over time. This is where parts of the foot will shift around when you’re walking or standing for long periods at a time. It is usually made up leather parts or other types of materials that help keep things sturdy, especially when parts around it start to give out during heavy use!

This part sits behind where you put your heel and its purpose is primarily stability by preventing excessive stretching over time on one spot of the upper at this area. The counter can come in different shapes including square or rounded.

Tongue

The tongue is a soft material that covers the top of your foot. It is usually made of leather or synthetic materials and can be removable, but some shoes have a permanent one to protect it from wear and tear.

Shank

This part provides the shoe with stability and support to help you do parts of your job. The shank can be found between parts of the sole and parts of the upper, which will make parts of your feet feel like they are adequately supported inside parts of your work boot!

The shank usually has a T shape. This makes it strong enough to do its job but also flexible enough that it doesn’t get in the way when moving around or bending parts of your foot. On many boots, this part is hidden under other parts like foam cushioning so people may not even know it exists if they don’t look closely! The most common kind is a heel-to-toe design, but some shoes have a midsole in between which offers better flexibility and comfort.

Waterproof Membrane

This doesn’t make waterproof boots or shoes, but rather boots with this feature are waterproofed using fabric membranes which are sewn into the openings between parts like the uppers and parts like the midsoles. This adds durability to all parts while keeping water out for parts like your toes, heels, ankles and other parts not covered by water resistant parts. The membrane can make parts waterproof or just water resistant.

Waterproof membranes also provide insulation against the cold and keep warmth close to parts like your feet to prevent cold from creeping in during winter months. This is done by trapping pockets of air around parts like your toes, heels, ankles and other parts that are not covered by water resistant parts.

Waterproof membranes are usually made out of polyurethane film that has been coated with a fluorocarbon resin on both sides for durability, transparency, flexibility and to enable it to become breathable so it doesn’t trap body humidity inside boots or shoes which would lead to foot rot over time. Breathability means allowing moisture vapor generated by perspiration escape so too much moisture does not build up inside parts of boots or shoes.

Breathable membranes are made out of ePTFE which is only 0.1 micron thick, but 8 times stronger than steel and 4 times more flexible than rubber. This means it’s very strong for its thickness, but still can stretch around parts like your toes, heels, ankles and other parts without ripping apart. It also insulates against the cold while at the same time allowing moisture vapor to escape so foot rot does not develop over time due to too much moisture build up inside parts like the uppers and parts like your feet that produce sweat.

Gore Tex is one of the most popular brands for breathable waterproof membranes because they’re durable and provide insulation where necessary, but let parts like your toes, heels, ankles and parts not covered by waterproof membranes breath so they don’t trap body humidity inside parts of boots or shoes. This leads to foot rot over time which isn’t healthy for parts like your feet. Breathable membranes come in 2 forms:

- Membrane only, where the top fabric is sewn to a non-breathable backing material that has no membrane properties.

- Membrane & lining which combines parts that are both breathable and waterproof into one single piece of fabric that gets inserted into parts like uppers using lamination techniques during manufacturing. Laminating parts together prevents water from getting through parts with openings such as those around your toes, heels, ankles and other areas where you need parts that are waterproof and parts you need parts breathable.

Vamp

The vamp is the portion of the boots that covers top of your feet. When you wear pants over the shaft, it’s the most apparent element of leather. So if your pants cover the boots’ shaft, make sure you’re satisfied with how it looks before purchasing.

Throat

The throats are the areas of your work boots that cover your calf. The throats will protect you from getting hurt while wearing them, so it’s important to make sure that they have a durable throat.

Draft Shields

These parts are meant to protect parts like your Achilles tendon from getting rubbed by parts like laces or tongues of shoes. A drafts shield prevents cold air from entering boots and thus keeps feet warmer in colder temperatures. It also reduces the likelihood that moist air will leave the boots through parts such as these which can be annoying, discomforting and even dangerous for parts like toes. Usually made out of plastic, carbon fiber or Kevlar, draft shields can attach via adhesive on some boots and on others they can be integrated into its design with no traces left over for anyone to see how it’s attached.

Instep

The instep is located between parts of boots that cover parts like your toes and parts that can protect your feet from getting hurt. The instep is the middle section of parts inside boots that don’t have support.

Piping

The piping, often known as a side seam, is the stitching that runs down the shaft’s sides and holds it together.

Different Materials Used For Work Boots Production

Different types of work boots are made from different materials, depending on the kind of protection and durability they need. Some common materials for making good-quality boots include: leather, cork, rubber (natural or synthetic), steel toes, and Kevlar® fabric.

Leather

Leather is a natural material that provides long-lasting use in all weather conditions without having to apply any type of treatment to it. It can be dyed many colors and has an appearance that varies in thickness as well as texture which make them perfect for custom orders. Leather also molds quickly so there’s less chances of getting blisters with these shoes. The downside is that if you don’t take care of your leather shoes properly then they will not last long. Also if you don’t know how to break in boots made of leather fast, it will create discomfort and will decrease life span.

Leather can be full grain or split grain leather depending on whether parts of boots or shoes have been made out of the upper part of the skin, which is called full grain leather, or just thinner sections that usually results when parts start peeling apart from using machines during manufacturing. If you’re looking at boots & shoes that use only full grain leather than it means they’ve been put together much more carefully and will last longer.

The different types of leather used in boots’ making are:

- Full grain leather

- Split Grain leather

- Printed leather

- Nubuck leather

- Suede leather

Cork

Cork is a renewable resource that has an antibacterial property to it making them suitable for people with foot fungus or odor problems and they don’t produce any noise when walking on cork so it’s perfect for warehouse workers who need to be quiet. Cork shoes are very light weight, but not as durable as leather boots because the material can wear out quickly in moist conditions. Excellent boots insoles can be made from corks.

Rubber

Rubber (either natural or synthetic) makes great insoles that provide absorption of shock and stability which reduces back pain if standing all day at work plus these soles do well in damp environments like farmlands or warehouses where there may be water puddles around so you’ll want rubber-soled boots if you’re working outdoors often. The downside of rubber is it doesn’t last as long and normally need to be replaced every year or two.

Toe Caps

Toe caps (Steel toe/ Composite toe/ Aluminum toe/ Moc toe) are common in safety footwear offer protection from falling objects, but the downside with these type of boots are there’s no grip on slippery surfaces like ice so they’re not good for jobs where you’ll have a lot of walking outside in winter conditions.

Kevlar® fabric

Kevlar® fabric provides lightweight strength that can resist wear and tear while also being resistant to water making them perfect work shoes for people who do maintenance tasks outdoors such as gardening, landscaping or construction because they will keep your feet dry while protecting them at the same time. The only problem is Kevlar® material isn’t flexible enough which makes wearing these work boots uncomfortable when bending down often, so they are better for people who stand all day.

Thermoplastic Polyurethane (TPU)

TPU parts are durable all-purpose parts that are commonly found in boots today. These parts will often times have two or more parts combined into one to create the part that you need for your shoe.

Production process of Safety Leather Work Boots

Tanning Leather

Tanning is the stage that determines the quality of leather, which in turn determines the quality and durability of work boots.

Cutting & Trimming

Cutting out parts and punching holes with thread, sewing on ribbons or metal eyelets to secure these laces inside the top, applying glues and soles, followed by trimming seams and decorating edges

Assembling

Attaching lining, insoles, heel counters (which are used as cushions), shanks (puts structure into material) followed by finishing with shoe trees which help maintain shape over time.

Packaging

The last step in this process is packaging up all of their work boots and sending them off to various retailers across the world

Know Your Work Boot

It is very important to know your boots’ things before you purchase the most suitable new pair.

Verify Features Before Purchasing

- Safety : Work boots should always be made with safety in mind and should be considered as safety shoes. This is why you want to make sure your boots have features such as safety toe and heel counters. These safety shoe features will protect you from any type of foot injury . Also, you want to make sure that your work boots have a high quality heel counter. This will slip resistance when wearing them.

- Durability : The most important thing about any type of footwear is durability. If you are going to be spending time outside or on the job, then you want to make sure that your boots are durable. It’s also important that they last for years without breaking down. The construction of the work boot, i.e. Cement or Goodyear Welt construction, should be able to withstand the harsh conditions of work, for example, extreme heat, compression hazards, abrasion, punctures

- Cost : Of course, you want your work boots to be durable, perfect for foot protection and last for years without breaking down. But they also need to be affordable. If they are too expensive, then people won’t purchase them with additional cost because it’s just not worth it.

- Comfort : You don’t want to wear uncomfortable boots when you go out in the cold or hot weather. When it comes to comfort, it’s important that your work boots have a high quality lining. You also want to make sure that they are lightweight and provide good support for your feet.

- Weight: The weight of a shoe is the total amount of mass (the combined material used to make it) plus any additional materials added by the manufacturer. A heavier shoe will generally feel heavier and be more stable than a lighter shoe.

Know Your Work Boot Size

This is a basic rundown of what the various parts of your work boot should look like, and how to measure them so you can determine which type will be best for you:

- Girth : The girth of the boot is how wide it is from side to side. This can be measured in inches or centimeters, depending on what type of measuring system you are using. For example, if you are a man, then you will want to buy a work boot that is about 1.5 inches wide from side to side.

- Width : The width of the boots can be measured in different ways as well. For example, it could be measured in centimeters or inches depending on what type of measuring system you are using. For example, if you are a man, then the width of your boots should be about 12 centimeters wide from side to side.

- Top : The top of the boot is where the laces will go through it. This can also be measured in different ways depending on what type of measuring system you are using. For example, if you are a man, then the top of your boots should be about 2 inches above the heel.

- Heel Measurement : The heel is where the foot will rest when wearing it. It can also be measured in different ways depending on what type of measuring system you are using. For example, if you are a man, then the heel should be about 1 inch high from the back of your heel to the front.

- Midsole Measurement : The midsole is where most of the shock absorbing things for your boot will come from. The midsole can be measured in different ways depending on what type of measuring system you are using. For example, if you are a man, then the midsole should be about 1 inch from the front to back of your work boot.

- Outsole Measurement : The outsole is where most of the traction for your boot will come from. The outsole can be measured in different ways depending on what type of measuring system you are using. For example, if you are a man, then the outsole should be about 1 inch wide from side to side.

Cement Construction vs Stitch Down Construction vs Goodyear Welt Construction of Work Boots

- Cement construction is an old-timey style that consists of gluing together parts of the upper with parts of the outsole using an extremely strong adhesive. This construction can increase your chances of having dryer feet by keeping water from entering into seams between parts where water often pools during everyday life. Cement construction also reduces its weight significantly over other styles, making it ideal for anyone working outdoors frequently.

- Stitch down construction has been used for years and is one of the most popular for a reason. It combines parts of the upper with parts of the outsole by stitching them together and thus creating more durable parts while adding extra ankle support over other styles like cement. Each stitch down boot is made up of multiple parts that are all stitched together. There are two main types of stitch down construction: single and double; Single stitch down boots consist of 5 parts, making it more lightweight than double stitch down boots which add another piece to add durability and further protect your feet from outside objects like nails or rocks poking into parts where they don’t belong.

- Goodyear Welt Construction is a type of construction that is also very popular with workers because it maximizes comfort and durability at the same time. This style consists of a strip of leather wrapped around a rubber outsole, which creates parts that are lightweight and durable. It’s an excellent choice for any worker who spends long hours on their feet since they tend to create parts where parts can support your feet more than other styles like cement or stitch down.

Have a minute to spare?

Let us quickly sneak through the interesting video by The Vintage Future to get more ideas on different parts of a boot :

In case you are interested, we have researched, tested and made a short list of the most durable work boots you can buy now. If you have a look and pick one, we may earn some commission for a cup of coffee, not bad, huh?!

| Image | Brand and Model | Toe Type | Durability Rating | Price Range | Price |

|---|---|---|---|---|---|

Top | Timberland PRO Men's Hyperion WP-M Industrial and Construction boot | Alloy Toe | Awesome | $$ | Check Reviews & Price |

| Caterpillar Men's Second Shift Steel Toe Work Boot | Steel Toe | Excellent | $ | Check Reviews & Price |

| Danner Men's Quarry USA 8-Inch Alloy Toe Work Boot | Alloy Toe | Excellent | $$$ | Check Reviews & Price |

| KEEN Utility Men's Pittsburgh Steel Toe Waterproof Work Boot | Steel Toe | Excellent | $$$ | Check Reviews & Price |

| Thorogood Men's American Heritage 6" Moc Toe Boot | Moc Toe | Excellent | $$ | Check Reviews & Price |

| Timberland PRO Men's Boondock Soft-Toe Industrial Work Boot | Soft Toe | Excellent | $$ | Check Reviews & Price |

| Irish Setter Men's 6" 83605 Work Boot | Soft Toe | Excellent | $$ | Check Reviews & Price |

| EVER BOOTS "Tank" Soft Toe Work Boot | Soft Toe | Excellent | $ | Check Reviews & Price |

| Dr. Martens, Men's Ironbridge Metatarsal Guard Work Boot | Steel Toe | Excellent | $$ | Check Reviews & Price |

| WOLVERINE Men's Overpass Composite Toe Work Boot | Composite Toe | Excellent | $$ | Check Reviews & Price |

Final Words

Your feet are precious and they deserve the best. You may have purchased or will purchase your pair of boots from online or from physical stores, but knowing the process of how safety footwear are made and the different parts of a work boot will help you make an informed decision on which ones to buy.

Have a nice Work Boots shopping! See ya all!

- Are Steel Toe Boots Safe? Debunking Myths and Unveiling Facts - July 23, 2023

- Ensuring a Firm & Safe Footing: An In-depth Guide to Safety Toes in Work Boots (Types, Features, & More) - July 17, 2023

- Silence the Symphony of Squeaky Steps: How to Stop Leather Boots from Squeaking (And Shoes Too) - July 3, 2023